SONY: HOW THE JAPANESE KAIZEN MENTALITY HELPED THE BRAND OVERCOME CRISES

- Af

- Forlag

Introduction to Kaizen Philosophy and its Relevance in the Japanese Context The word "kaizen" is a combination of two Japanese characters: "kai" (change) and "zen" (for the better). Literally translated, it means "continuous improvement." However, kaizen transcends the literal meaning and becomes a philosophy of life, especially in the Japanese corporate environment. Sony, one of the largest technology companies in the world, has adopted this mentality since its inception and has used it as one of the pillars to overcome crises throughout its history. In the post-World War II period, Japan faced enormous economic and social challenges. Rebuilding the country required not only government efforts but also a change in business mindset. It was in this context that the concept of kaizen began to gain traction, driven by figures such as Toyota's Taiichi Ohno and W. Edwards Deming, an American consultant who profoundly influenced Japanese management practices. Kaizen is not just about big innovations or radical changes. It is about small, everyday improvements that, over time, add up to significant transformations. At Sony, this approach was applied at all levels of the organization, from the production line to senior management. Sony founder Masaru Ibuka believed that innovation and quality were direct results of a culture of continuous improvement. Fundamental Principles of Kaizen Focus on People: Kaizen values teamwork and the participation of all employees, regardless of their hierarchical level. Incremental Improvements: Rather than seeking drastic changes, kaizen encourages small, daily adjustments. Eliminating Waste: Identifying and eliminating inefficient processes is essential to optimizing resources. Respect for the Work Environment: A healthy and respectful environment motivates employees to contribute ideas. Results Orientation: Every action must be evaluated based on its concrete impacts. Practical Example Imagine that you are a line manager for a television production line at Sony. In applying kaizen, you decide to implement daily five-minute meetings with your team to discuss problems and suggestions. During one of these meetings, an employee suggests adjusting the position of a machine to reduce the time spent handling components. This small change saves five seconds per unit produced. With a daily production of 1,000 units, this results in savings of over an hour per day. This example illustrates how small improvements can have a significant impact.

© 2025 Max Editorial (E-bog): 9781779749154

Udgivelsesdato

E-bog: 15. april 2025

Andre kan også lide...

Vælg dit abonnement

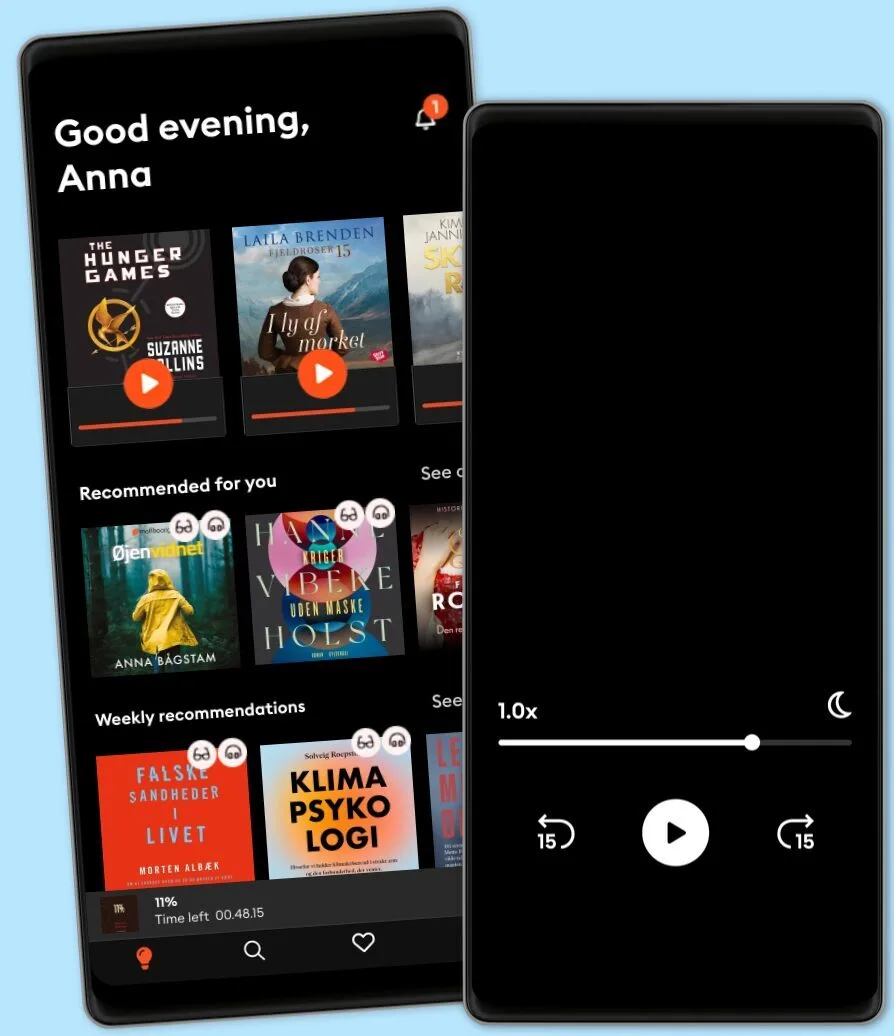

Over 1 million titler

Download og nyd titler offline

Eksklusive titler + Mofibo Originals

Børnevenligt miljø (Kids Mode)

Det er nemt at opsige når som helst

Premium

For dig som lytter og læser ofte.

129 kr. /måned

Eksklusivt indhold hver uge

Fri lytning til podcasts

Ingen binding

Unlimited

For dig som lytter og læser ubegrænset.

159 kr. /måned

Eksklusivt indhold hver uge

Fri lytning til podcasts

Ingen binding

Family

For dig som ønsker at dele historier med familien.

Fra 179 kr. /måned

Fri lytning til podcasts

Kun 39 kr. pr. ekstra konto

Ingen binding

179 kr. /måned

Flex

For dig som vil prøve Mofibo.

89 kr. /måned

Gem op til 100 ubrugte timer

Eksklusivt indhold hver uge

Fri lytning til podcasts

Ingen binding

Har du en rabatkode?

Indtast koden her