What you can learn from Japan’s seven-minute miracle

- Af

- Episode

- 185

- Published

- 4. jan. 2021

- Forlag

- 0 Anmeldelser

- 0

- Episode

- 185 of 256

- Længde

- 20M

- Sprog

- Engelsk

- Format

- Kategori

- Økonomi & Business

Today we are going to look at a different kind of innovation.

It's not technology. It's not patentable, and I'm not sure it's scalable. But it is important.

It turns out that the story behind a Japanese viral video can teach us a lot about the future of work. It's an example of Japanese innovation at it's best

I think you'll enjoy it.

Links

The Seven-Minute Miracle video

Leave a comment

Transcript Welcome to Disrupting Japan, straight talk from Japan's most successful entrepreneurs. I'm Tim Romero and thanks for joining me. I have a special story for you today. No guests. No playful banter. Today it’s just you and me and a story about Japanese innovation at its very best. And it’s also the real story behind a famous video about Japan that you’ve probably seen a dozen times on the internet and on western news shows. But like so many stories about Japan, the media gets this one wrong; or at least get it incomplete. They leave out the part of the story that actually teaches us something important about Japan. But there is something pretty amazing going on once you dig into it, and so that’s what we are going to do. The story I’m talking about is the so-called “seven-minute miracle” of the Shinkansen cleaning crew. If you live in Japan, you’ve probably witnessed this personally, and I’ll put a link to the video in the show notes for any listeners who have not already watched it.

The Seven Minute Miracle The Shinkansen is both an engineering and an operational marvel. There are times when JR East is running trains three minutes behind each other at 320 kilometers per hour. To make this work requires an insane commitment to schedule. A departure is only considered to be on-time if happens within fifteen seconds of its scheduled time; no earlier, no later than 15 seconds. And most trains arrive within six seconds of their scheduled time. Part of making this work means that at Tokyo station, each train has only a 12-minute turnaround-time. It takes about five minutes to get the current passengers off and the new passengers on, which leaves seven minutes for cleaning. In those seven minutes, a crew of 22 people clean 1,000 seats, wipes down all the tray tables, exchanges seat and headrest covers, turns the seats 180-degrees to face the new direction, cleans the floors and bathrooms, empties all the wastebaskets, collects any forgotten articles from under the seats or in the overhead racks to turn into the lost and found, adjusts the window blinds, and generally makes sure everything on the train is neat and tidy. In seven minutes. And the cleaners do it all with an efficiency and grace that seems more like the mastery of a craft than the execution of a duty. When they are done, usually with time to spare, they assemble on the platform at the front of the train and bow in unison to the passengers who are about to board. Sometimes the passengers even clap. And a few minutes later, a new train arrives, and this is repeated for each of the 120 to 170 Shinkansen trains that depart Tokyo every single day. It’s amazing to watch, and a few years ago CNN picked up the story, and the whole world was, quite rightly. impressed. However, the CNN story focused on how Japanese employees are so efficient and take pride in their work. And that’s not quite true. I mean, these employees clearly are, and Japanese workers certainly can be dedicated and efficient, but anyone who tells you that Japanese employees are just naturally dutiful and efficient has clearly never had to manage Japanese staff. In fact, even in this celebrated case, it was not always so. This is a relatively recent development, and looking at the innovations that began in 2005 can also tell us a bit about where the gig-economy is headed and the kind of innovation that Japan can bring to the world. The Making of a Miracle The company responsible for the seven-minute miracle is Tessei, and in terms of corporate culture, they are about as far away from a startup as you can get. They were founded in 1952 as a cleaning subsidiary to the JR rail-monopoly and were handed over to JR East when JR was broken up in 1987. Back in 2005, both the Japanese character, and the Shinkansen schedules were very much the same as they are today, but things were not well at Tessei or in their cleaning crews. The job was considered dirty, dangerous, and dead-end, so it was hard to both recruit and retain employees. Morale was low. Performance was poor. Delays were frequent. Tessei management responded to this the way managers worldwide tend to respond to these situations. They increased training and supervision and upped the number of checks and inspections. Unsurprisingly, this had the effect of pushing morale down even further. The delays increased, and so did accidents and customer complaints. At this point, JR East sent in Teruo Yabe to take over business planning at Tessei and he began to change things. In fact, he began doing things that seemed to go against the very concept of efficiency. The previous goal was to make the cleaning crews almost invisible. To the passengers, this rapid cleaning was to happen almost magically. Yabe turned this idea on its head. He began a program that he called “Shinkansen Theater” He changed the uniforms from the pastel tones designed to blend in with the trains’ interior to a bright red that ensured that the cleaners would stand out. The passengers could clearly see that the cleaners were there and what they were doing. Which is the first step to appreciating what they are doing. Waiting to board is much less annoying when you understand why you are waiting, and hey when you think about it, cleaning 1,000 seats in seven minutes and doing a good job of it, well that is pretty impressive. Yabe made other changes as well. For example, he allowed the cleaners to speak with the passengers, where before they had been prohibited, in the name of both efficiency and lack of training. Most of the questions passengers ask cleaning crews turn out to be related to cleaning or the station layout, and the ones they can’t answer? Well, no one seemed too bothered by an honest “I’m sorry, I don’t know.” Importantly, however. it turned out that allowing this communication not only did not distract the cleaners from their job, but It increased the passengers’ understanding of and appreciation for the job they were doing. In fact, about this time, something rather remarkable began to happen. As the Shinkansen passengers began to see what an amazing job the cleaners were doing, the passengers began picking up after themselves, and the amount of trash left behind for the cleaners to clean up began to drop. Yabe also made important cultural changes. He encouraged employees to report the best things about their coworkers to their managers. He took suggestions from the employees and developed a career path by which part-time cleaners had a clear path to a full-time job and the full-time cleaners could enter the management ranks. Efficiency improved. Training costs dropped. Employee morale and retention skyrocketed. And within a few years, Japan’s seven-minute miracle came to be. And Yabe-san, Tessei, and the cleaning crews have received well-deserved international recognition for what they achieved. Rail operators from all over the world come to study these cleaning crews, and Harvard Business School has developed case studies to document and understand this incredible turnaround. The Story Behind the Miracle And that’s great. But there is something very important and innovative here that tends to get overlooked. On one hand, this is the kind of just-so story about Japan that the foreign media loves. It’s positive and uplifting, and at first glance it seems to be one of those stories of diligence and efficiency that only happens in Japan. But it doesn’t have to be. It’s easy and somehow satisfying to attribute the diligence of the cleaning crews and the tidiness of the passengers to something uniquely Japanese. But it’s not. This was a change in behavior. Neither the Shinkansen cleaners nor the passengers were doing this in 2005 but they were in 2010, and they still are today. So what really changed? The real innovation here did not involve introducing efficiency. It involved introducing multiple inefficiencies that enabled greater, sincere human connections, and those connections are what lead to greater efficiencies. OK. That’s a lot to unpack so let’s step through it. Almost every change Yabe-san introduced risked decreased efficiency and quality of service in the short term. Having the cleaners distracted from their jobs by talking with passengers, decreasing measurement and oversight. Even making the cleaning crews more visible to the customers went against the hospitality and travel best practices which hold that this kind of work is to take place out of sight and all friction for the customer is to be removed. But everything Yabe-san did increased the possibilities for human connection. Not the usual, scripted staff-customer communication or the usual manager-staff meetings, but inefficient, unnecessary communication not directly related to completing the task at hand. Rather than managing for control and compliance, he was managing for transparency and connection. Internally this not only resulted in a skyrocketing of morale but an outpouring of creative ideas. The Tessei staff not only came up with innovations that improved their own jobs, but helped design the shape of the bins on the new Hokuriku Shinkansen Line, and they came up with the idea for the nursery and baby areas in Tokyo Station. And, of course, it was this feeling of human connection that resulted in passengers cleaning up after themselves because they did not want to create extra work for someone they had just seen working so hard.

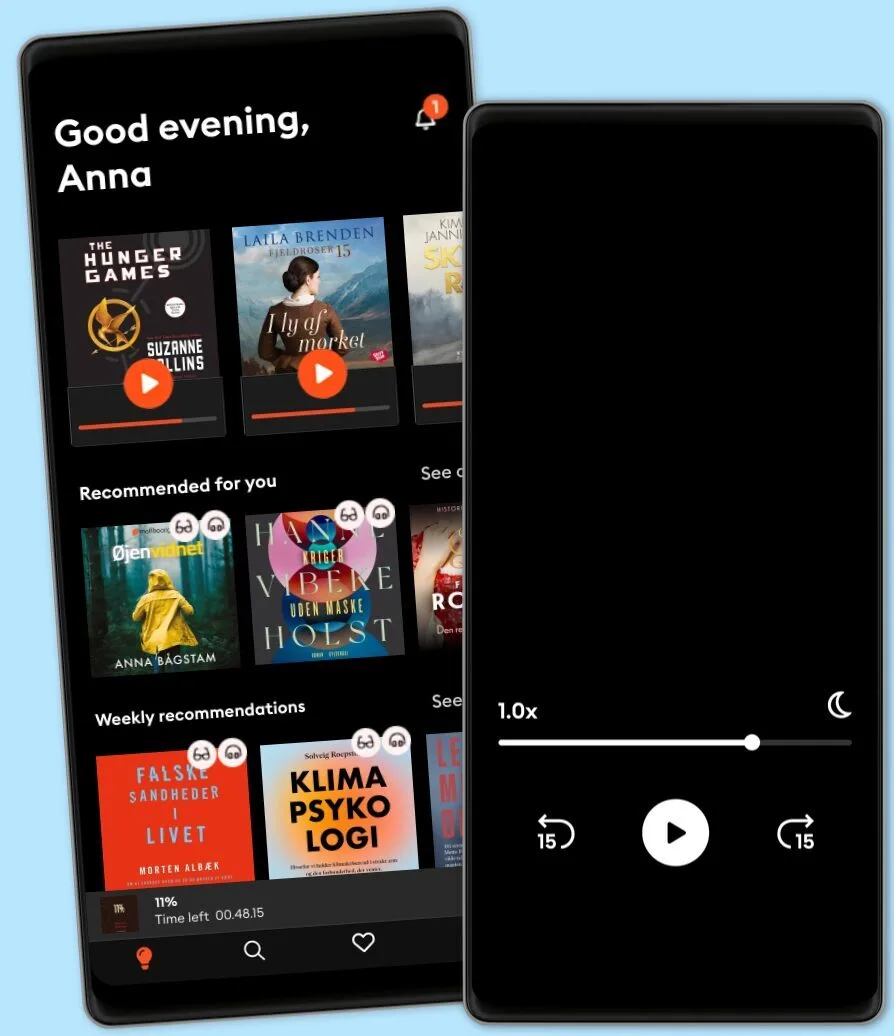

Lyt når som helst, hvor som helst

Nyd den ubegrænsede adgang til tusindvis af spændende e- og lydbøger - helt gratis

- Lyt og læs så meget du har lyst til

- Opdag et kæmpe bibliotek fyldt med fortællinger

- Eksklusive titler + Mofibo Originals

- Opsig når som helst

Other podcasts you might like ...

- The Journal.The Wall Street Journal & Spotify Studios

- The Can Do WayTheCanDoWay

- 1,5 graderAndreas Bäckäng

- Redefining CyberSecuritySean Martin

- Networth and Chill with Your Rich BFFVivian Tu

- Maxwell Leadership Executive PodcastJohn Maxwell

- Mark My Words PodcastMark Homer

- Ruby RoguesCharles M Wood

- EGO NetCastMartin Lindeskog

- The Pathless Path with Paul MillerdPaul Millerd

- The Journal.The Wall Street Journal & Spotify Studios

- The Can Do WayTheCanDoWay

- 1,5 graderAndreas Bäckäng

- Redefining CyberSecuritySean Martin

- Networth and Chill with Your Rich BFFVivian Tu

- Maxwell Leadership Executive PodcastJohn Maxwell

- Mark My Words PodcastMark Homer

- Ruby RoguesCharles M Wood

- EGO NetCastMartin Lindeskog

- The Pathless Path with Paul MillerdPaul Millerd

Dansk

Danmark