The Real Reason Japan Can’t Innovate & What to Do About It – Xenoma

- Af

- Episode

- 78

- Published

- 13. mar. 2017

- Forlag

- 0 Anmeldelser

- 0

- Episode

- 78 of 256

- Længde

- 37M

- Sprog

- Engelsk

- Format

- Kategori

- Økonomi & Business

From the transistor radio to the Walkman to the Gameboy and the Playstation, Japan has always been both a leading force in hardware technology and a Mecca for gadget geeks.

Over the past ten years, however, Japanese dominance in consumer hardware has been slipping away. The falling price of not just computing, but of manufacturing and prototyping has resulted in some amazing connected devices appearing all over the world. But while Japan’s large corporations have been falling behind, Japan’s startups have been rushing ahead.

Today we sit down with Ichiro Amimori of Xenoma to talk about why he left a successful 20-year career in materials science at FujiFilm to found a company that makes a low-cost, washable motion capture shirt they call e-skin. It’s a order of magnitude cheaper than existing technology and opens up the possibility of applications in gaming, sports technology and heath and medicine.

We also talk about the challenges Japanese enterprises and universities have turning fundamental research into salable products, and a few trends that might just turn that situation around.

It’s a great interview and I think you’ll enjoy it.

Show Notes for Startups

What is e-skin and why is it important? Why leave a 20-year career to start a risky startup How FujiFilm managed to innovate and survive How to attract developers to a new hardware platform Why most early adopters are outside Japan How Japan lost it's lead in the gaming industry How motion capture can help the elderly Why Japanese companies have trouble in new markets The future of open innovation in Japan

Links from the Founder

Everything you ever wanted to know about Xenoma A deeper dive on e-skin Ichiro's personal blog (in Japanese) Follow Ichiro on twitter @ichiroamimori Friend him on Facebook

[shareaholic app="share_buttons" id="7994466"] Leave a comment

Transcript from Japan Welcome to Disrupting Japan- straight talk from Japan’s most successful entrepreneurs. I’m Tim Romero, and thanks for joining me.

You know, Japan has always been the land of cool hardware, from the Zoom recorder I’m talking into to the Gameboy, to the Play Station, to the Walkman, to the transistor radio. Japan has always been a mecca to gadget geeks. Of course, things have changed in recent years, the falling price of not just computing, but of manufacturing and prototyping has resulted in some amazing connected devices appearing all over the world.

And Japan, if we’re being honest with ourselves here, is falling a bit behind.

Ichiro Amimori is a small part of the solution to this. He left a 20-year career in material science to found a company that produces what they call e-skin. It’s a tight fitting shirt that can sense the movements of its wearer and act as an inexpensive, accurate, motion capture device. It’s price and durability is something you might find a little bit surprising.

Of course, with a cool hardware available now, attracting developers to your new platform, no matter how cool, is something of a challenge these days. Even Google is having problems in this area. Ichiro and I dive into some detail about how Xenoma is solving this. We also talk about the challenges that Japanese enterprises and universities have turning fundamental research into real products. And the steps that they’re taking to solve them.

But you know, Ichiro tells that story much better than I can, so let’s hear from our sponsors and get right to the interview. [pro_ad_display_adzone id="1404" info_text="Sponsored by" font_color="grey" ]

[Interview] Tim: I’m sitting here with Ichiro Amimori of Xenoma. You guys make e-skin. It’s like clothing, it’s motion capture, it’s just a shirt, really, but thanks for sitting down with us.

Ichiro: Nice meeting you.

Tim: Tell us more about what Xenoma is, and what this shirt really does.

Ichiro: So we are a startup company from the University of Tokyo, and we established a company November 2015. What we are making is the e-skin, which is a smart apparel. We are not saying it is wearable, because shirts are obviously wearable. As you can see here, this is just a shirt. Stretchable shirt.

Tim: Right, and it’s an audio podcast, so it’s kind of hard to explain. But it just looks like normal, stretchable, workout wear with kind of a Tron design to it.

Ichiro: Right, everybody says that. Actually, so this Tron design, you see the silver stuff, is the electric circuit, which is stretchable. So in here, there is wiring and sensors, you can touch.

Tim: We’ll put pictures on the website, so everyone can know what it looks like. But, the circuits don’t seem to be wires. They’re printed on here and, are they printed? Stitched?

Ichiro: We are not saying the manufacturing process in detail, but we are using many kinds of manufacturing process which is conventional. The point is that… you see this silver stuff, so many people say, “Is this conductive?” Actually, the silver stuff is not conductive. All the conductive part is in the silver stuff, because when you sweat, you may have an electric shock due to the water. Then all the electronics is well-insulated on both sides. This silver stuff is one insulation layer.

Tim: So the silver stuff is really just to make it look like Tron.

Ichiro: Yes, it is just a design. We could make it black, but why don’t we make it like Tron?

Tim: So the sensors really work by the stretching of the fabric.

Ichiro: Yes. We are saying that this is a motion capture shirt, without using camera. What we are doing is not just capturing motion, but we are measuring the deformation of the shirt caused by motion. For instance, when we bend our elbow, the elbow part is stretched. Then we see that the shirt, the elbow is bent. So that is the principle that we are doing.

Tim: That makes sense. Is it washable as well?

Ichiro: Yes of course. Right now, you are not seeing this part, we call it hub, which is a controller. And when we are using it, we need to attach on the shirt like this.

Tim: For the listeners, this is a small barbell shaped device that you attach across the chest of the shirt.

Ichiro: Yeah and this part is not machine washable. But we can take it off and then all the rest of the shirt is machine washable.

Tim: By the way, how do you determine machine washable? Is there a standard for this?

Ichiro: That is a very good question. I did not know that, but there is an ISO standard that is for machine washable. ISO A, and ISO B, and ISO C.

Tim: So three levels of machine washable.

Ichiro: They also have ASTM, American style test. What we chose was ISO C, which is closer to ASTM. What we did was, we washed in 40 degree hot water for a hundred times.

Tim: A hundred times? They have got standards for everything. That must have taken a while.

Ichiro: That actually took two and a half months. Why we stopped at 100 times is not from breaking, but just the time.

Tim: Traditional motion capture equipment has wires connecting the user back to the computer. But obviously, there are no wires, it’s all wireless. So the snap on controller obviously has a wireless transmitter in the device. Are there other sensors in there?

Ichiro: Actually in this controller, we named it the hub, there is an accelerometer and gyro in here to measure the moving of the center of the body.

Tim: Things that wouldn’t stretch this shirt.

Ichiro: Also, in here, there is a battery and a [UNCLEAR] (8:06) computer and Bluetooth as their transmitter. This is kind of the CPU of this system, and once we take it off, we can wash everything. This is the most important part of that.

Tim: Looking at it, can this also be used to monitor breathing or heart rate?

Ichiro: We can measure breathing, respiration. Because when we are breathing, our chest is moving and then we can measure respiration. Unfortunately, we cannot measure heart rate. I can say that, at this year’s [UNCLEAR] (8:48) in Las Vegas in January, we demonstrated the baby monitoring system. We named it the e-skin cool, which contains the temperature sensor, which is a digital sensor. Once we can plug in the digital sensor on the shirts, we can change to anything. For example, heart rate sensor, SPO2 pulse sensor, or even motion sensor can be embedded in our shirts.

Tim: So the baby device, it’s just a little wearable shirt to let parents know their baby is still moving around. I want to drill down into the different uses of this later. But right now, let’s back up a bit. I want to ask a couple questions about you. You seem like a pretty non-typical startup founder. You got a degree from Todai, you got a PhD in material science from Brown, you were at Fujifilm for 20 years. What made you decide to leave a successful career at Fujifilm and start this crazy startup?

Ichiro: It might be crazy, I agree. Actually, when I was in Fujifilm, I had been working on making new businesses for 18 years. When I joined Fujifilm and started my career, the photography film business was nearly gone. I had a chance to start a new business in Fujifilm. So for me, making new businesses in big company or making new businesses in a startup is almost the same. What I felt when I left Fujifilm was, since I had been working for a long, long time. I was too tired of using a long, long time for decision making by someone else. I thought that I could make it by myself. I think it was a good time for me to start by my own power. Then I left Fujifilm.

Tim: So Fujifilm is not involved in this startup at all. It’s completely…

[pro_ad_display_adzone id="1653" info_text="Sponsored by" font_color="grey” ]

Ichiro: Recently, actually, they’re a good company for innovation. They’re starting pharmaceutical businesses and healthcare businesses.

Tim: Actually, Fujifilm is a very interesting company in terms of innovation. If we back up 20 years,

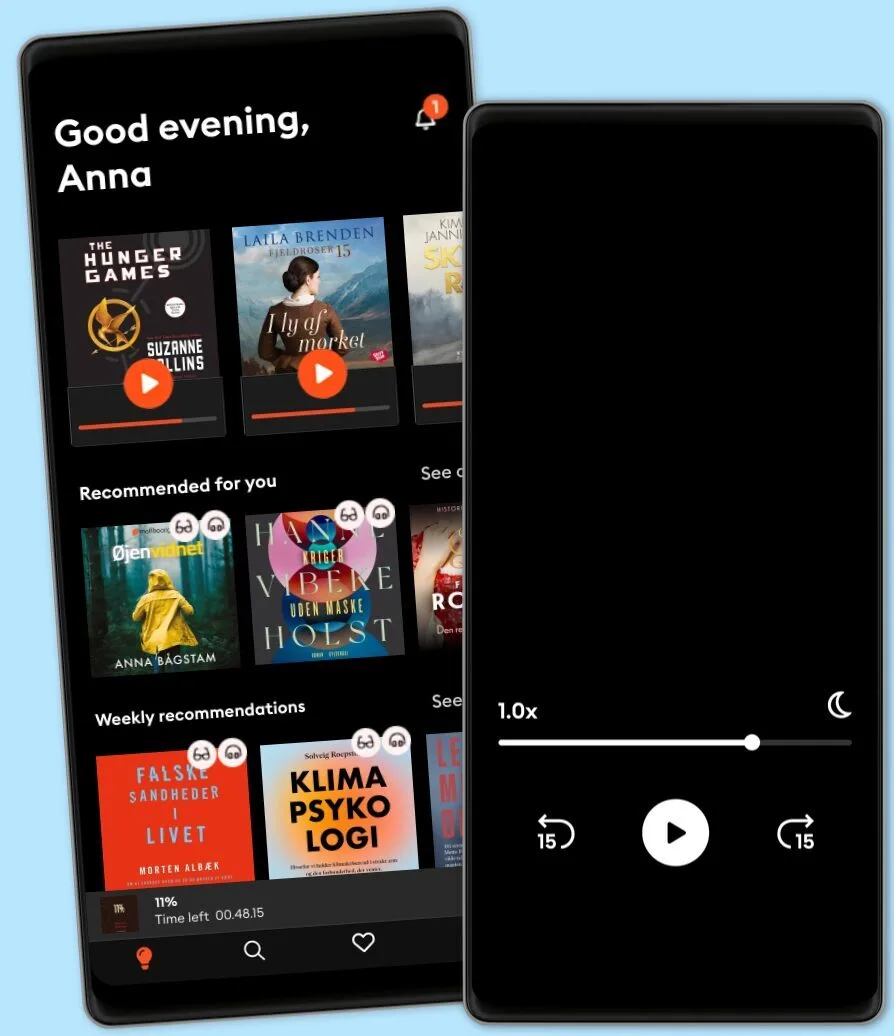

Lyt når som helst, hvor som helst

Nyd den ubegrænsede adgang til tusindvis af spændende e- og lydbøger - helt gratis

- Lyt og læs så meget du har lyst til

- Opdag et kæmpe bibliotek fyldt med fortællinger

- Eksklusive titler + Mofibo Originals

- Opsig når som helst

Other podcasts you might like ...

- The Journal.The Wall Street Journal & Spotify Studios

- The Can Do WayTheCanDoWay

- 1,5 graderAndreas Bäckäng

- Redefining CyberSecuritySean Martin

- Networth and Chill with Your Rich BFFVivian Tu

- Maxwell Leadership Executive PodcastJohn Maxwell

- Mark My Words PodcastMark Homer

- Ruby RoguesCharles M Wood

- EGO NetCastMartin Lindeskog

- The Pathless Path with Paul MillerdPaul Millerd

- The Journal.The Wall Street Journal & Spotify Studios

- The Can Do WayTheCanDoWay

- 1,5 graderAndreas Bäckäng

- Redefining CyberSecuritySean Martin

- Networth and Chill with Your Rich BFFVivian Tu

- Maxwell Leadership Executive PodcastJohn Maxwell

- Mark My Words PodcastMark Homer

- Ruby RoguesCharles M Wood

- EGO NetCastMartin Lindeskog

- The Pathless Path with Paul MillerdPaul Millerd

Dansk

Danmark