One soil startup’s unusual and risky scaling secret

- Af

- Episode

- 224

- Published

- 5. feb. 2024

- Forlag

- 0 Anmeldelser

- 0

- Episode

- 224 of 256

- Længde

- 29M

- Sprog

- Engelsk

- Format

- Kategori

- Økonomi & Business

Most sustainability startups struggle to find sustainable business models

Towing, however, has found their solution, and their customers are seeing 20% to 70% increases crop yields.

Today we sit down with Towing co-founder Teppei Okamura and he explains why even such a drastic yield improvement required an innovative production and distribution model to achieve scale.

We also talk about the advantages (and the challenges) of working with university research teams, how environment policy and carbon credits affect innovation in sustainable agriculture, and Towing's joint research project with JAXA, Japan's space agency, on developing farming in space.

It's a great conversation, and I think you'll enjoy it.

Show Notes

How Towing is revitalizing depleted agricultural soil Achieving and verifying 20 to 70 % yield improvements The pros and cons of research collaboration with Japanese universities The high-tech business model behind dirt How to develop the economic incentives needed to make sustainable agriculture profitable Towing's distributed business model that reduces storage and distribution costs Farming in space and the most important part of getting it to work Why Japan is a good market for Agtech startups How carbon offset pricing influences sustainable agriculture The advantages of starting a startup when the economy is good vs when times are bad.

Links from the Founder

Everything you ever wanted to know about Towing Follow Towing on Twitter @TOWING_0227 Friend Teppei on Facebook Government's take on space farming [pdf] Interesting information in Japanese

Founder interview at Nagoya University Towing's recent TV appearance Agricultural carbon credits

Transcript Welcome to Disrupting Japan. Straight Talk from Japan's most successful entrepreneurs. I'm Tim Romero and thanks for joining me. Cheaper Than Dirt. Well, anyone who works in modern agriculture will tell you that's not necessarily very cheap these days. Maintaining soil quality is hard and soil revitalization is expensive. Well, today we sit down and talk with Teppei Okamura, co-founder of Towing, a startup that has developed a sustainable and affordable soil additive that is resulting in a 20 to 70% increase in crop yield and is now being sold to farmers throughout Japan. And Towing addresses the common scalability challenge that these kinds of agricultural tech startups inevitably face by using an innovative production and distribution model that should allow them to achieve meaningful and perhaps even global scale. We talk about the challenges of launching a university spin out using licensed IP, why so many genuinely innovative agTech startups never managed to reach sustainable commercial scale, and about Towing's ongoing collaboration with Japan's space agency to develop the technologies and protocols to make agriculture and space a reality. But, you know, Teppei tells that story much better than I can. So, let's get right to the interview.

Interview Tim: So, we're sitting here with Teppei Okamura of Towing, who's using microorganisms and bio charcoal to revitalize agricultural soil. And thanks for sitting down with us today. Teppei: Thank you. Thank you for inviting me. Tim: I gave just a very, very high level explanation of what Towing does, and I'm sure you can explain it much better than I can. Teppei: What we produce is artificial soil. Basically we make soil from bio-char, which is made from any like organic materials and like waste from rice industry or like chicken industry or any waste. The organic waste can be used and we grow our basic microbes in the bio-char. And we make that into very good soil or good soil additives, especially good for organic farming. Tim: And from what I understand, while it can usually take up to five years to revitalize agricultural soil Towing’s process can do it in in one month. Teppei: Yes. Usually like making soil farm takes very long time and it's very complicated organism. It's like a black box. So, it's a little hard to know what condition the soil is now. It takes long time, but still like many farmers fail to make a good soil. But with our soil additives, when farmers put our soil additives in their soil, like it changes their physical structure of soil. And also it gives good nutrient, also it gives good microbes with the combination of those and it can make the soil into very good condition within very short time. Tim: From what I understand, your customers reporting yield improvements anywhere from 20% to 70%? Teppei: Yeah, it varies. Like it really depends on the soils they use and crops and also fertilizer they use. And also when the soil is already very good condition, it's a little hard to make it better. Tim: So, the 20 to 70% really depends on the more on the condition of the original soil. Teppei: Yes, yes. In the reality, not so many fields are in best condition with our soil conditioner. Those like rich soil can be even richer and like poor soil can be richer. Tim: So, tell me about your customers. Who's using this soil? Teppei: There are many types, but like rice farmers, tomato farmers, strawberry, it's actually applied for any crops. But it's better for farmers who use organic fat rice more or who has high value product. Tim: Alright, well tell you what, I want to get into a deeper dive on the market and the technology in a minute, but before that, I want to talk a little about how Towing was founded. So, you and the team are still relatively new. You just launched out of Nagoya University back in 2020, right? Teppei: Yes. So, at that time our Kohei Nishida was a student master and I was a researcher and actually I was in the same study group, but I've already done my doctorate degree. At the beginning, like we were more focusing on the agriculture in space actually. Tim: I definitely want to get back and talk about agriculture and space in a minute because that's a really interesting topic. But, so the founding team, everyone was part of the same study group in Nagoya University? Teppei: Three are from our study groups and two are from car industry actually. So, they're engineers. Tim: So, my understanding is the core technology, or at least some of the core technology that towing is using was developed by the National Institute of Agriculture and Food Industry. Teppei: The original technologies was invented by the institution and our study group was a research member, Nagoya University and that institution, we were studying that technology together. Tim: And so how does this work? I know a lot of Japanese universities are really focusing on commercializing their research, commercializing their IP. So, is the institute still involved in the startup? Are they licensing the IP? Are they investors? Teppei: Yeah, the regional professor, he was the advisory kind of position because that institution of the patent, so we had to work out patent right matter. So, we sometimes asked him for advice. Tim: So, what is the structure of the patent licensing? Teppei: Basically there were three or four companies who used to use that patent attend. So, we had a contract to license and we made it like four only those companies who had been using that patent. Tim: So, the companies that were already using it could continue to use it, but they couldn't license it to any further companies other than Tokyo. Teppei: Yes, exactly. That's the way we were making the contract. But that's the only for the first patent. Like after that we've been doing a lot of development on that technologies. So, we also have patents for like business model or patents for the extended technology. Tim: Is Towing still doing like joint research and development with either Nagoya University or the institute? Teppei: Basically we do study with Nagoya University and we have laboratory in the university. Tim: Excellent. Let's talk a bit about the overall market and the business model. So, I mean, bio-char is pretty common. A lot of companies are selling it. So, what's different about what Towing is doing? Teppei: Our technology is adding value on bio-char. Like bio-char is like already used in agriculture sector as a soil conditioner, but sometimes they have problem because it has high, pH, that's alkaline type of material. So, when you use that bio-char too much, it's actually not good for crops. So, we add microbe in it and make good soil conditioner that makes soil field faster than like just bio-char itself. Tim: Is your long-term goal to produce the enhanced bio-char product and sell that to the farmers directly? Or is your goal more of to sell the technology and the service to the companies already producing bio-char to allow them to produce a higher value product? Teppei: At the moment, like we actually sell products to farmers but our main business model is we don't have plant. We let customers have a plant, for example, like chicken industry company producing eggs or like chicken meat. They have lot of waste and they have to get rid of that every day. Some of those company have like high cost throwing those material away. For those company we offer a service introducing a plant to produce soil additive made from bio-char so they can have like bio-char furnace. Tim: That's interesting. So I mean, with bio-char being, as popular as it is now, do a lot of these factories and farms already have bio-char furnaces? Teppei: Yeah, it's getting more common. Some those agriculture companies, they have those bio-char furnace. Tim: That's interesting. And so actually let's walk through the whole business model of this then. So, if a poultry processing plant, if a chicken farm is producing bio-char, they're not selling it to farmers, what are they doing it? Are they using it directly? Are they selling it to a chemical company? Teppei: Often they sell that to farmers,

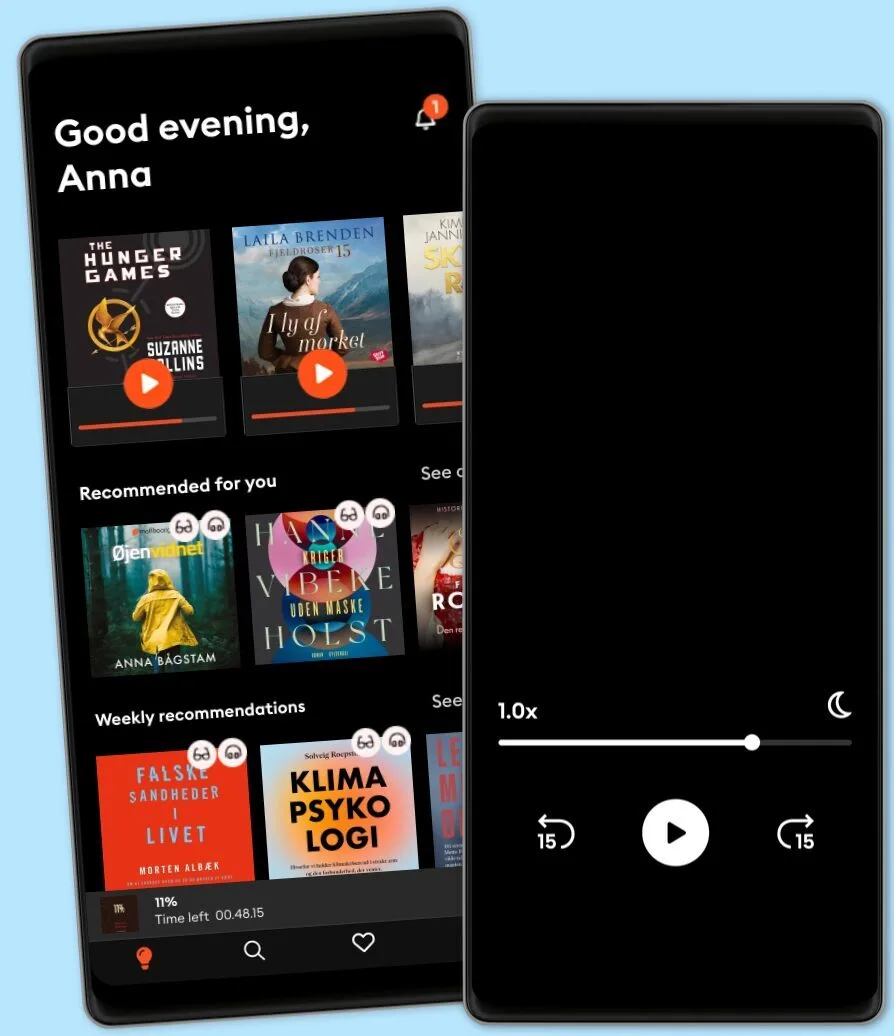

Lyt når som helst, hvor som helst

Nyd den ubegrænsede adgang til tusindvis af spændende e- og lydbøger - helt gratis

- Lyt og læs så meget du har lyst til

- Opdag et kæmpe bibliotek fyldt med fortællinger

- Eksklusive titler + Mofibo Originals

- Opsig når som helst

Other podcasts you might like ...

- The Journal.The Wall Street Journal & Spotify Studios

- The Can Do WayTheCanDoWay

- 1,5 graderAndreas Bäckäng

- Redefining CyberSecuritySean Martin

- Networth and Chill with Your Rich BFFVivian Tu

- Maxwell Leadership Executive PodcastJohn Maxwell

- Mark My Words PodcastMark Homer

- Ruby RoguesCharles M Wood

- EGO NetCastMartin Lindeskog

- The Pathless Path with Paul MillerdPaul Millerd

- The Journal.The Wall Street Journal & Spotify Studios

- The Can Do WayTheCanDoWay

- 1,5 graderAndreas Bäckäng

- Redefining CyberSecuritySean Martin

- Networth and Chill with Your Rich BFFVivian Tu

- Maxwell Leadership Executive PodcastJohn Maxwell

- Mark My Words PodcastMark Homer

- Ruby RoguesCharles M Wood

- EGO NetCastMartin Lindeskog

- The Pathless Path with Paul MillerdPaul Millerd

Dansk

Danmark