How to sell innovation in cut-throat, low-margin industries

- Af

- Episode

- 227

- Published

- 29. apr. 2024

- Forlag

- 0 Anmeldelser

- 0

- Episode

- 227 of 256

- Længde

- 44M

- Sprog

- Engelsk

- Format

- Kategori

- Økonomi & Business

Some industries need to be dragged kicking and screaming to innovation.

When margins are tight and profits are small, CEOs often don't want to spend a dime on the promise of increased efficiencies or long-term savings, and so external leverage is needed.

Today we talk with Shinya Shimizu, founder and CEO of Elephantech, who explains how he found that leverage in his mission to make the global technology supply chain more environmentally friendly.

We explore how Elephantech and other startups are helping the world meet net-zero targets, strategies for scaling manufacturing startups, and how you can make money while doing good in the world.

It's a great conversation, and I think you'll enjoy it.

Show Notes

The surprising impact of circuit boards on global CO2 emissions Growing from a kickstarter camping into a multi-million dollar startup How to raise debt financing rather than equity financing How Elephantech is selling eco-friendly solutions in a low-margin commodity industry How they built their first factory, and Shinya never wants to build another one How to scale a manufacturing startup Advice on successfully selling to and collaborating with Japanese enterprise How to take a deep tech startup global without massive amounts of capital Advice for sustainability startups on how to survive and thrive in cost-conscious industries When government regulation is good for startups and when it's damaging The danger of the wrong kinds of founder role models in Japan.

Links from the Founder

Everything you ever wanted to know about Elephantech Follow Shinya on Twitter @shinyashimizu_e Connect with Shinya on LinkedIn

Transcript Welcome to Disrupting Japan. Straight Talk from Japan's most successful entrepreneurs. I'm Tim Romero and thanks for joining me. Circuit boards are one of those things that are everywhere, but that we really don't think about very much. Personally my only direct experience with circuit boards was years ago and involved a fair amount of cursing and a lot of solder burns. But printed circuit boards or PCBs, or a $90 billion global industry that is highly standardized, tightly controlled, and surprisingly damaging to the environment. Well, Shinya Shimizu and the team at Elephantech are changing that, they've not only developed the technology to re-engineer PCB manufacturer to be more environmentally friendly and less expensive, but they've also built their first factory and are now selling to some of the world's largest manufacturers. Elephantech is a great example of how startups can succeed while making a positive contribution in this world. And Shinya also gives some great practical advice about how to sell to large enterprises as a new startup. How to raise money for capital intensive growth, and how to introduce new innovation into a low margin cutthroat industry. It's really quite an amazing story of their journey from a small Kickstarter project 10 years ago to make a pen that lets you draw working electrical circuits to selling PCB technology to some of the world's largest manufacturers today, to just maybe fundamentally changing the way circuit boards get made tomorrow. But, you know, Shinya tells that story much better than I can. So, let's get right to the interview.

Interview Tim: So, we're sitting here with Shinya Shimizu, the CEO and founder of Elephantech. The first company in the world to mass produce printed circuit boards using an inkjet printing, echo friendly, sustainable manufacturing process. Shinya: Yeah. Sure. Tim: That's longer to say than I thought. But thanks for sitting down with us. Shinya: You're welcome. So, I'm really happy to be here. Tim: Well, I try to explain what you do in that big mouthful of an introduction, but I think you can probably explain it better than me. So, what does Elephantech do? Shinya: So, Elephantech is going to completely change the way of manufacturing electronic circuits, completely changed with drastically, environmentally better, of course, and cost effective way. And our goal here is like probably in 10 years, or at least 15 years from now, the most of the circuit boards in the world, I mean, including iPhone and laptop, any kind of electronic circuits are made by our technology. Tim: Well, and I think kind of the core of your innovation is most circuit boards today are produced using a subtractive process… Shinya: Yeah. Subtractive method. Tim: And you use an additive method. Shinya: Right. I said completely different way of manufacturing. Electronic circuit means existing way uses subtractive method and ours additive, purely additive manufacturing. That's the biggest difference. So, the conventional way is subtractive, which means, so, circuit boards are copper wires are placed on plastic boards, that circuit boards. And to make the circuit boards existing way, like laminate the copper foil to the plastic board and then remove unnecessary part from the copper file so that you use the remaining part as wires. But during the process, 80 or 70% of copper is dispersed and not used. So, which is material efficiency is very bad, and cost-wise, it's bad. So, that's the existing way. Our way is completely different. So, we first print the copper with inked printing technology and then increase the thickness of copper by plating technology. Plating makes the copper crystal grow. So, it's purely additive. So with that technology, it's inherently good. Tim: Right, right. Well, less waste all around. So, like you're claiming a 70% reduction of copper use and 95% reduction of water use. And 75% reduction in CO2 emissions. And I was amazed at how much circuit board production contributes to CO2 emissions. Shinya: Absolutely. Yeah. That's probably bigger than anyone think. Apple, I would say, for example, Apple is one of the biggest carbon producer in the world because they are making a lot of things. But 10% of their total carbon footprint, including their travel, including manufacturing and any kind of carbon footprint, 10% of them are from circuit board manufacturing. Tim: So, that's not just their supply chain, that's their total carbon footprint. Shinya: Total Carbon footprint. Tim: Holy Cow. That is really a big contribution. That's big. Shinya: That is big. And Apple is, of course aiming at net zero by 2030. So, that 10% is significant. Tim: Yeah. Well, tell me about your customers. So, who's using Elephantech technology and what's their motivation for doing it? Shinya: Yeah, the motivation is mainly decarbonization. Exactly, decarbonization. So, last year -- I cannot really talk about a lot about like undisclosed client of course, but in an already disclosed clients like Litton for example. Litton is not the most famous company in the world, but it's a big company. So, one fourth of global laptop keyboards are manufactured by Litton. So, last year we had a joint press release of MOU sign kind of ceremony with Litton and Litton motivation to use our board exactly decarbonization. The point is like Litton customers are normally Western countries. I would say it's not their customer. It's not normally Taiwanese companies. So, they're European companies or North American companies. And they really choose supplier by environmental aspect. Tim: I really want to dig in on how those consumer pressures are changing supply chain in general. But before we do that, I want to talk a little about you. So, I mean, you founded Elephantech back in 2014. Shinya: Yeah, it's long ago. Tim: But it was AgIC, right? As a Kickstarter campaign. Shinya: Sure. Oh, you know that. Tim: Oh, I've been fans of you guys for a long time. Shinya: Thank you. Yeah, thank you. Tim: Yeah. You had that cool little marker where you could… Shinya: Yep, yep. Yeah, it's cool. Little marker. Tim: Tell us about that. Shinya: Yeah. Before starting that company. So, I was working for McKinsey as a management consultant. And while working for McKinsey, I was looking for interesting scientific things especially from the universities. And because I believed, and I now still believe that university technologies are normally underused. So, there are a lot of technology that can potentially change the world, especially in Japanese universities, I would say. So, I was looking for innovations and I found this technology that is invented by a professor Kawahara, who is now the professor at the University of Tokyo. But the circuit markers, I'd say it is definitely not directly connected to our final goal. Tim: Yeah. Why the kickstart? So, I mean, when I first thought saw that, I was like, oh, well that's kind of cool. But what are these guys going to do with it? So, did you know your direction from the beginning? Shinya: No. So, this is my first company and when I founded this company I was 25 years old. And honestly, so I got lost, I would say. So, I mean, the technology itself was really, I would say immature. It's not as sophisticated as what it is right now. So, that professor's technology cannot directly print metal on plastic substrate. And all of the circuit boards are basically plastic substrate. And they started from printing copper on paper. It's interesting and it's can be a good seed, but copper printed paper cannot be used for industrial use. Tim: Okay. So, just from the outside, I was watching you guys go from like the handheld markers for drawing circuits to a kind of an inkjet on printer and now on the circuit board. But these were different technologies. Shinya: Honestly. Yes. Honestly, yeah. I mean, so we say like to investors normally, so it's all connected, but scientifically, so these technologies are not directly connected, I would say. Tim: Well, I guess there's a lot of kind of know-how and experimentation that connect them. Shinya: Sure. So, the first period is like not directly connected to what we are doing currently, but during the process,

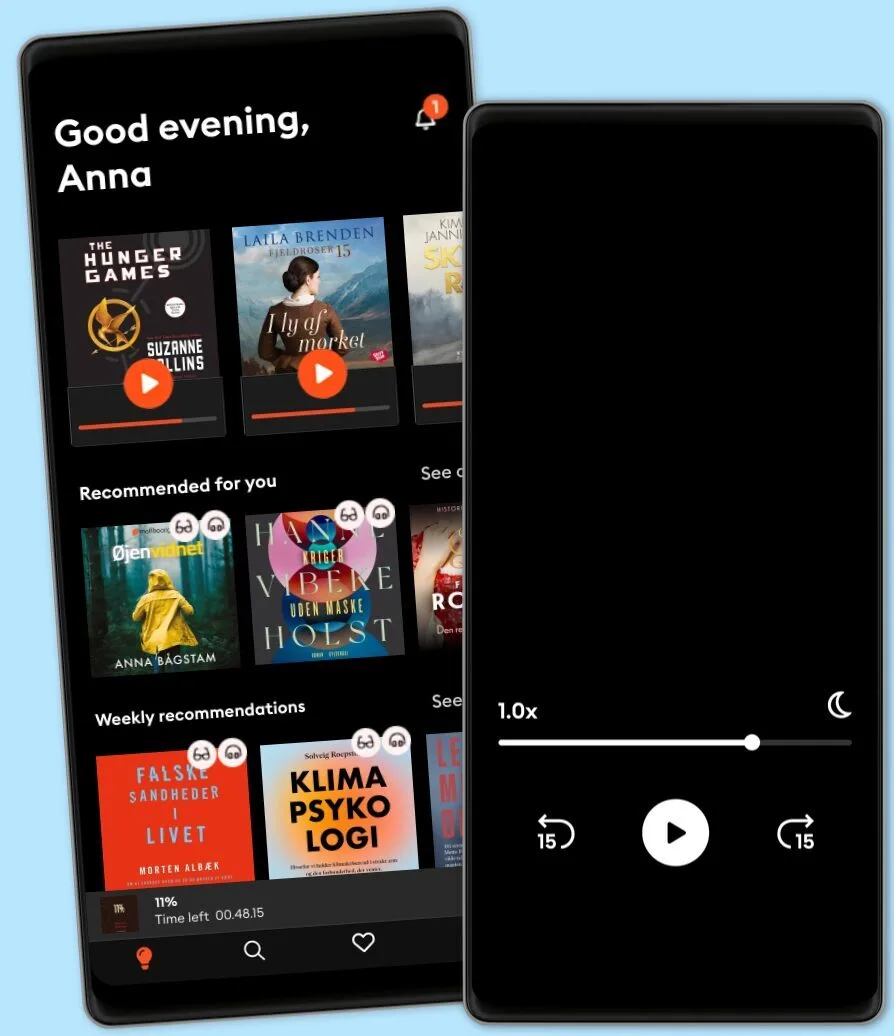

Lyt når som helst, hvor som helst

Nyd den ubegrænsede adgang til tusindvis af spændende e- og lydbøger - helt gratis

- Lyt og læs så meget du har lyst til

- Opdag et kæmpe bibliotek fyldt med fortællinger

- Eksklusive titler + Mofibo Originals

- Opsig når som helst

Other podcasts you might like ...

- The Journal.The Wall Street Journal & Spotify Studios

- The Can Do WayTheCanDoWay

- 1,5 graderAndreas Bäckäng

- Redefining CyberSecuritySean Martin

- Networth and Chill with Your Rich BFFVivian Tu

- Maxwell Leadership Executive PodcastJohn Maxwell

- Mark My Words PodcastMark Homer

- Ruby RoguesCharles M Wood

- EGO NetCastMartin Lindeskog

- The Pathless Path with Paul MillerdPaul Millerd

- The Journal.The Wall Street Journal & Spotify Studios

- The Can Do WayTheCanDoWay

- 1,5 graderAndreas Bäckäng

- Redefining CyberSecuritySean Martin

- Networth and Chill with Your Rich BFFVivian Tu

- Maxwell Leadership Executive PodcastJohn Maxwell

- Mark My Words PodcastMark Homer

- Ruby RoguesCharles M Wood

- EGO NetCastMartin Lindeskog

- The Pathless Path with Paul MillerdPaul Millerd

Dansk

Danmark